Raceway Systems-Cable Management Solutions- Ladder Racks- Wholesale ladder Racks-Cable Management Solutions- WireTrays - Distribution Racks- Raceway- Relay Racks- CableTies-Cable Management- Cable Wraps-Finger Duct Panels

| Live Support by Citricle |

American Tele Data carries a complete line of cable management solutions including cable trays, wire trays, ladder racks, distribution racks, raceway and raceway systems that can be tailored to meet your specific needs. American Tele Dataprovides a complete line of cable management products from several manufacturers including Cablofil, Snaketray, Hendry, Newton, Signamax, Ortronics, ICC Ladder Racks, Cable Manager,Homaco, ADC, Bailywick Systems, Damac, ADC, and others. We offer wholesale ladder rack options to make every telephone closet or network bay installation neat, well organized and secure.American Tele Data Tele Data's ladder racks are are available in 3, 4, 5 6, 7 ft, 10 ft. versions, and come in either a black powder coated or polished aluminum finish. For added cable management, vertical cable channels can be added to standard distribution racks. Our new ladder racks come in 5 foot lengths that contracotrs have been requesting to lower shipping costs. Now we can ship several ladder racks- 5 feet or less via UPS-meaning lower shipping costs. Need Raceway Systems? -more info

|

Cablofil Raceway Systems |

Vutec-Wiremaid Raceway Systems |

SnakeTray Raceway Systems |

ICC Raceway Systems |

-

Cable Management Panels

Cable Management Panels![]()

1u - 5 Ring |

1u - 6 Ring PT ATD34-208010 |

1u - 20 Ring PT ATD34-207200

|

2u - 5 Ring PT ATD34-207000 |

2u - 8 Ring PT ATD34-207001 |

2u - 9 Ring PT ATD34-207300 |

2u - Channel PT ATD34-207800 |

2u - Dual Channel PT ATD34-208200 |

PT ATD34-211200 |

Bridging Mount PT ATD34-211300 |

1u Cable Management Rings

|

Aluminum Distribution Rings |

Cable Routing Mushrooms |

Cable Mgmt Bar ATD34-351900 |

Cable Mgmt Tiewrap Bar ATD34-352500 |

2 x 6 Wall Stud Cable

ATD34-620000

|

19" Rack or Cabinet Mount

ATD34-LPG2008 |

|||

|

Cable Management Racks

Cable Management Racks  Distribution Racks Below

Distribution Racks Below

Data Cabinets-Racks-Raceways Data Cabinets-Racks-Raceways |

|

||

|

Cable Management Racks- Accessories

Raceway Systems

Vertical Rings

Rack Mount Rear Cable Management Bar

Metal Ring Panels

Metal Interbay Panels

Extended Cable Management Bracket

Clip Panels

Cable Management Ring Panels

Cable Management Panel Covers

Cable Management Interbay Panels

Cable Management Finger Duct Panels

Blank Panels

Distribution Rack-ICC CABLE MANAGEMENT RACK, BLACK, 7 FT ICCMSCMRH7 -- black (In Stock)

Distribution Rack-ICC CABLE MANAGEMENT RACK, BLACK, 7 FT ICCMSCMRH7 -- black (In Stock)

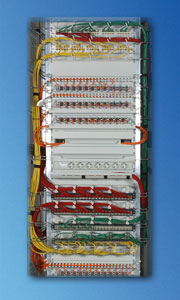

ICC's standard 19 inch cable management rack utilizes a hybrid steel construction, making it ideal for use with heavy data or electronic equipment. It has integral 6 inch cable channels along both sides of the rack to manage and conceal bulk cable vertically along the inside of the rack. The rack has cable tie anchor points throughout the cable channel to secure cable bundles with Velcro® cable ties. Includes 25 mounting screws

.

Cable Management Racks by Signamax

Cable Management Racks by Signamax ![]()

Cable Management Racks combine the features of a high quality relay rack, as well as effective cable routing and raceway facilities, all in one complete unit. All aluminum cable management rack allows for the mounting of a wide variety of 19 inch wide patch panels, hubs, switches, and related rack mount equipment. The rack is supplied with cable hangers, cable ties and generous provisions for organizing incoming cables for termination with effective patch cord management on the front. Racks are shipped with all assembly required plus an accessory pack that includes 20 cable ties, 16 cable hangers, 40 cuphead mounting screws, and grommeting for cable routing cutouts.

Standard equipments racks are designed for 19 inch rack mount equipment. Racks are constructed of aluminum and are available in a variety of standard heights. Each rack is drilled and tapped on both the front and the rear rails with 10-32 holes on EIA spacing. Standard rack finish is black. Racks are packaged knocked down for easy shipment.

Part Number |

Cable Management Rack Description |

1977-1032B |

Signamax Cable Management Rack, 19"W x 84"H, Black Finish, 10-32 Holes |

Cable Management Racks

Part Number |

Cable Management Rack Description |

RR-84B |

Signamax Equipment Rack, 19"W x 84"H, Black Finish, 10-32 Holes |

RR-48B |

Signamax Equipment Rack, 19"W x 48"H, Black Finish, 10-32 Holes |

RR-84 |

Signamax Equipment Rack, 19"W x 84"H, Milled Finish, 10-32 Holes |

RR-48 |

Signamax Equipment Rack, 19"W x 48"H, Milled Finish, 10-32 Holes |

------------------------------

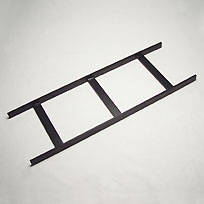

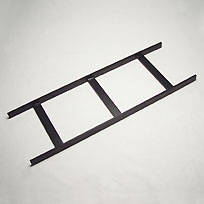

Five Foot Ladder Racks-ICC Part Number: ICCMSLST05

Five Foot Ladder Racks-ICC Part Number: ICCMSLST05

Runway- Raceway section is designed to support horizontal cable running over-head. Constructed of heavy duty 16-gauge steel with a durable powder coated finish, it can be easily attached to all ICC racks. Part Number: ICCMSLST10 10 ft*., Runway, 12 in. Wide *We Have Shorter Lengths!! |

Runway- Raceway radius bend section is used to change the horizontal cable running over-head in a 90° vertical direction to route cables downward to a vertical ladder. Part Number: ICCMSLOR90 Runway Radius Bend, 12 in. Wide |

Runway-raceway radius bend section is used to change the horizontal cable running over-head in a 90° vertical direction to support ceiling cable entry. Part Number:ICCMSLIR90 Runway Radius Bend, 12 in. Wide |

Turn section is designed to change the horizontal cable running over-head in a 90° flat turn. Part Number:ICCMSLFT90 Runway 90° Turn, 12 in. Wide |

|

|

|

|

Click Here for Installation Instructions and detailed pictures of Ladder Rack

Raceway Systems Available

|

Cablofil Raceway Systems |

Vutec-Wiremaid Raceway Systems |

SnakeTray Raceway Systems |

ICC Raceway Systems |

ICC Finger Duct- Click Here -------

ICC Finger Duct- Click Here ------- ------- ICC Racks- Cable Management

------- ICC Racks- Cable Management

Horizontal Finger Duct

Horizontal Finger Duct  Vertical Finger Duct

Vertical Finger Duct

|

Hendry Racks! |  |

Distribution RacksClick --------Ladder Racks Click

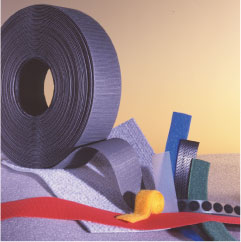

NEW.......Cable Wrap-CableTies.....

![]() Cable

Ties-Cable Wrap-Cable Catch-Cable Hangers

Cable

Ties-Cable Wrap-Cable Catch-Cable Hangers

ATD's cable management racks are made of rugged steel and feature a black powder coating. All rack side rails have openings for cable routing, and provide cable tie anchors in various locations. These racks are available in 4 and 7 foot models. In addition to floor mounted racks, a variety of wall mount racks and brackets are available to fill specialized applications. To add to the versatility of the distribution and cable management racks, American Tele Dataoffers a selection of shelves to support components that do not need to be rack mounted.

Cable management panels are available to support bulk cable or patch cords horizontally or vertically. These panels come with standard metal, or durable plastic rings. Plastic snap-on covers can be added to the plastic panels to create a neat, well-organized appearance. Brackets, vertical rings, and management bars round out ATD's Cable Management Solution.

New Ladder Rack Systems!

Call (866) 342-3721 Or Click On The Chat Button At The Top Of The Page To Talk To One Of Our Representatives

Wholesale Ladder Racks, Ladder Rack Systems & Raceway Systems

|

NEW Ladder Rack Runway Mounting Kits NEW Straight Ladder Rack Runway Key features:

ICC Raceway System Cutting Tool-Part# ICACSTPE60 This ICC Raceway System Cutting tool make cutting raceway a "snap".

| |

|

|

Designed to complement American Tele Data Tech Supply's line of racks, panels and cross-connect products, we offer Hendry, B-line, NewtonKewaunee and ICC's, ladder rack system. This ladder rack system offers a complete set of cable installation, routing and management components that are engineered for configuration flexibility and installation versatility. Please note our ladder rack products below including our ladder rack inside corner, ladder rack outside corner, and ladder rack flat turn models below.

ICC Raceway System Cutting Tool-Part# ICACSTPE60 This ICC Raceway System Cutting tool make cutting raceway a "snap".

|

Runway section is designed to support horizontal cable running over-head. Constructed of heavy duty 16-gauge steel with a durable powder coated finish, it can be easily attached to all ICC racks. Part Number: ICCMSLST10 10 ft*., Runway, 12 in. Wide *We Have Shorter Lengths!! | Runway radius bend section is used to change the horizontal cable running over-head in a 90° vertical direction to route cables downward to a vertical ladder. Part Number: ICCMSLOR90 Runway Radius Bend, 12 in. Wide | Runway

radius bend section is used to change the horizontal cable running over-head in

a 90° vertical direction to support ceiling cable entry. Part Number:ICCMSLIR90 Runway Radius Bend, 12 in. Wide | Turn section is designed to change the horizontal cable running over-head in a 90° flat turn. Part Number:ICCMSLFT90 Runway 90° Turn, 12 in. Wide |

|

|

|

|

Click Here for Installation Instructions and detailed pictures of Ladder Rack

| ITEM NUMBER | DESCRIPTION | ||

| ICCMSLST10 | Runway Section, 12-inches Wide x 10-foot Length | ||

| ICCMSLFT90 | 90? Turn Section, 12-inches Wide, flat turn. | ||

| ICCMSLIR90 | Inside Radius Bend Section, 12-inches Wide | ||

| ICCMSLOR90 | Outside Radius Bend Section, 12-inches Wide | ||

| ICCMSLAWSK | Kit, Wall Support, 12-inches Wide | ||

| ICCMSLTWSK | Kit, Wall Support, Triangle, 12-inches Wide | ||

| ICCMSLVWBK | Bracket, Vertical Wall Mount | ||

| ICCMSLCMRK | Kit, Ceiling Mount and Rod (2 Threaded rods included) | ||

| ICCMSLMFFK | Kit, Foot Floor Mount | ||

| ICCMSLRRBK | Bracket, Ladder to Relay Rack, 12-inches Wide | ||

| ICCMSLEBSK | Kit, End-to-end Butt Splice | ||

| ICCMSLTJSK | Kit, Runway Section, T-Junction Splice | ||

| ICCMSLCRPK | Kit, Cable Retaining Posts (includes 2 posts) | ||

| ICCMSLCRDK | Runway Center Radius Drop, 12-inches Wide | ||

| Miracel 19" Distribution Rack-Lab Rack NO 19 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miracel 19" Distribution Rack – Network Rack NS 26 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Replace X with the digit representing your colour choice .1 = RAL 9011 / RAL 7035 ■ Door trim RAL 9011 black ■ Visible surface of the cover RAL 7035 light grey .8 = RAL 9011 / RAL 7021 ■ Door trim RAL 9011 black ■ Visible surface of the cover RAL 7021 black grey |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Miracel 19" Distribution Rack

| Miracel 19" Distribution Rack NS 19.8, single winged | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miracel 19" Distribution Rack – Network Rack NS 25 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Miracel 19" Network Equipment Rack NG 800

|

■ cable entry via plinth and cover Variants For the installation of Load rating Degree of protection Tests Material / Finish Colour Supply schedule How supplied Rack Suites |

| Miracel NG800 (Width 800mm) with glass door, single-winged | Order Number | ||||||

| type | nominal depth | height | weight | ||||

| T [mm] | t1 [mm] | H [U] | H [mm] | h [mm] | [kg] | ||

| with side panels | 800 | 730 | 23 | 1320 | 1052 | 77 | 01.135.649.1 |

| 37 | 1920 | 1652 | 107 | 01.135.651.1 | |||

| 41 | 2120 | 1852 | 115 | 01.135.652.1 | |||

| 46 | 2320 | 2052 | 124 | 01.135.653.1 | |||

| without side panels | 800 | 730 | 23 | 1320 | 1052 | 70 | 01.135.655.1 |

| 37 | 1920 | 1652 | 97 | 01.135.657.1 | |||

| 41 | 2120 | 1852 | 104 | 01.135.658.1 | |||

| 46 | 2320 | 2052 | 113 | 01.135.659.1 | |||

.

standard depths of 3, 4, 5, and 6 inches

5. standard lengths of 10, 12, 20

and 24 feet

Solid Bottom cable tray is generally used for minimal heat generating

electrical or telecommunication applications with short to intermediate support

spans of 5 feet to 12 feet.

3. Trough Cable Tray provides:

1. Moderate

ventilation with added cable support frequency and with the bottom configuration

providing cable support every 4 inches. Available in metal and nonmetallic materials.

2. standard widths of 6, 12, 18, 24, 30, 36 inches

3. standard depths of 3,

4, 5, and 6 inches

4. standard lengths of 10, 12, 20 and 24 feet

5. fixed

rung spacing of 4 inch on center

Trough cable tray is generally used for

moderate heat generating applications with short to intermediate support spans

of 5 feet to 12 feet.

4. Channel Cable Tray provides:

1. an economical

support for cable drops and branch cable runs from the backbone cable tray system.

2. standard widths of 3, 4, and 6 inches in metal systems and up to 8 inches in

nonmetallic systems.

3. standard depths of 1¼-1¾ inches in metal

systems and 1, 1 1/8, 1 5/" and 2 3/16 inches in nonmetallic systems

4. standard length of 10, 12, 20 and 24 feet

Channel cable tray is used for

installations with limited numbers of tray cable when conduit is undesirable.

Support frequency with short to medium support spans of 5 to 10 feet.

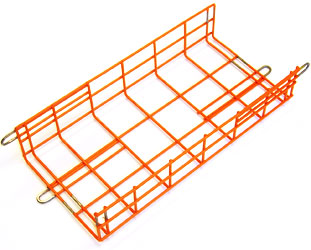

5. Wire Mesh Cable Tray provides:

1. A job site, field adaptable support system

primarily for low voltage, telecommunication and fiber optic cables. These systems

are typically steel wire mesh, zinc plated.

2. standard widths of 2, 4, 6,

8, 12, 16, 18, 20, and 24 inches

3. standard depths of 1, 2, and 4 inches

4. standard length of about 10 feet (118")

Wire Mesh tray is generally

used for telecommunication and fiber optic applications and are installed on short

support spans, 4 to 8 feet.

6. Single Rail Cable Tray provides:

1.

These aluminum systems are the fastest systems to install and provide the maximum

freedom fort cable to enter and exit the system.

2. Single hung or wall mounted

systems in single or multiple tiers.

3. Standard widths are 6, 9, 12, 18,

and 24 inches.

4. Standard depths are 3, 4, and 6 inches.

5. Standard

lengths are 10 and 12 feet.

Single Rail Cable Tray is generally used for

low voltage and power cables installations where maximum cable freedom, side fill,

and speed to install are factors.

What materials / finishes are available for the various cable tray systems?

1. Steel (Min. Yield = 33KSI) (35 KSI for Stainless)

1. Plain: hot rolled

pickled and oiled steel per ASTM A569 (Commercial Quality) or A570 (Structural

Quality)

2. Pre-Galvanized: mill galvanized steel per ASTM A653 CS (Commercial)

or SS (Structural) G90

3. Hot Dip Galvanized After Fabrication: plain steel

which is hot dipped after fabrication per ASTM A123.

4. Stainless Steel: type

304 or 316L fully annealed stainless steel

2. Aluminum (Min.Yield =

23 KSI)

1. 6063-T6 or 5052-H32 alloy per ASTM B209

3. Fiber Reinforced

Plastic (FRP)

1. Polyester and Vinyl Ester resin systems available

2.

meet ASTM E-84 smoke density rating; Polyester 680, Vinyl Ester 1025

3. Class

1 Flame Rating and self-extinguishing requirements of ASTM D-635.

Now that I know what types of cable trays are available, what configurations are available?

1. Straight sections are available to route cables in a horizontal or vertical

plane.

2. Fittings are available to route cables in various directions in

either the horizontal or vertical planes. Typical examples of fittings include

elbows, tees, crosses, and risers. Each of these fittings are available in various

radii and bend angles.

3. Covers are accessories and shouldn't be in here

unless splices etc. are included.

After selecting the type of cable tray and configuration required, what support methods are available?

1. Trapeze Support (Single or Multi-tier)

2. Hanger rod clamps, "J"

hangers

3. Center Hung Support

4. Wall Support

5. Underfloor Support

6. Pipe stanchions or other structures

Each

of these support methods are preferable in different applications. For instance,

trapeze supports may be desired in an application where cables will be pulled

through the cable tray. Center hung supports, on the other hand, are generally

used when cables will be installed from the side of the cable tray. Center hung

supports are especially useful when future cable additions are desired. Wall supports

and underfloor supports are useful when ceiling structure is not available or

undesired. Outdoor installations are controlled by the structures available to

support the cable tray.

Before selecting the type of cable tray, cable tray

configuration(s), and support method desired, what additional information do I

need to supply to the cable tray manufacturer for them to best understand and

satisfy my needs?

1. Where? Job site and installation considerations

1. Outdoor

1. supports

available affect the length and strength requirements

2. environmental loads,

ice, wind, snow, and possibly seismic

3. corrosion requirements affect the

materials and finishes

4. classified hazardous locations affect the cable

types acceptable

2. Indoor

1. support locations available affect the

length and strength of the system

2. industrial installation may require a

200 lb. Concentrated Load

3. commercial or institutional installation may

make system appearance, system weight, and space available important factors

4. environmental air handling area may affect cable types, cable tray material,

or cable tray type and need for covers

5. classified hazardous locations affect

the cable types acceptable

2. What?

1. Type and number of cables to support

1. NEC cable fill requirements

dictate size, width and depth, of system

2. cable support requirement may

control bottom type

3. largest bending radius of cable controls fitting radius

4. total of cable weight determines load to support

2. Future requirements

1. cable entry / exit freedom

2. design partially full or an expandable system

3. support type to allow for needs

B-Line Cable Management Racks

B-Line Cable Management Racks

Manage Your Cable While Managing Your Budget.

Now, installers have access to the most feature rich cable management system in the industry...introducing Cooper B-Line's RCM+. Offering simplified cable management, a more flexible solution for all installations and a reduced total installed cost. RCM+ has all the configurations you need for your rack supported cable management requirements.

Flexibility -

Need gates on the left, but fingers on the right? No problem. How about adding doors on the back? Again, no problem! The RCM+ open system design offers countless options and solutions to deal with issues of cable access and cable routing...like those that are created by increasing demands for faster data transmission and higher cable density. The RCM+ incorporates an innovative modular unit concept with total interchangeability of parts over all units. All rearrangement and modification of the cable management system is done easily in the field. Flexibility...based on your application needs now and in the future.

Affordability -

Our RCM+ cable managers offer all the features of higher priced systems, PLUS features that aren't offered on products priced at two, three and four times as much. Also, because of the way the RCM+ is designed, you will find significant labor savings, dramatically improved cable routing and access options. All part of a system that can be tailored to almost any need.

Installability -

No matter what your requirement is, RCM+ can be installed in whatever configuration you need, on whatever standard 2-post rack you have or want. The clean, simply designed appearance blends with the widest range of architecture and environments. If you require retrofitting a cable manager to an existing rack, or if you are looking to add additional racks and accessories, RCM+ will cure all of your cable management headaches.

Features & Benefits:

360° cable routing... from anywhere, to anywhere, through anywhere.

360° cable routing... from anywhere, to anywhere, through anywhere.

The open back design permits cable to enter or exit the cable manager at any RMU level, resulting in more direct routing to any point on the rack or an adjacent cable manager. This means less cable density, looser bundling and faster moves, adds and changes. The advantages of the open back design are amplified by the open side feature of double-sided managers.

Efficient, lower cost cable installation.

The 1/4" accessory mounting holes spaced every 1/2 RMU extend along the entire height of the RCM+. They are an integral component of the open system design. Permitting quick attachment of a wide variety of cable management devices, they are used to support, segregate and route cables going in all directions, whether entering, leaving or passing through the manager.

The 1/4" accessory mounting holes spaced every 1/2 RMU extend along the entire height of the RCM+. They are an integral component of the open system design. Permitting quick attachment of a wide variety of cable management devices, they are used to support, segregate and route cables going in all directions, whether entering, leaving or passing through the manager.

Assists with data integrity by reducing cable density.

The RCM+ takes full advantage of the cable pass-through openings on the side of the new, deeper racks. The open sides created by spaced-apart mounting, allow cable to pass through the cable manager to an adjacent rack or into either cable manager through the open back.

Compatible with advancements in rack designs and rack supported components.

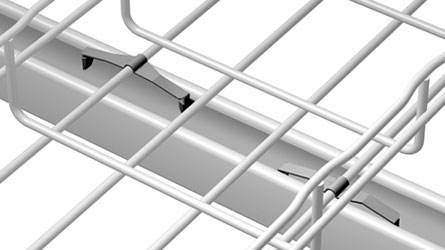

The RCM+ introduces a new system that consists of cable retention gates that uniquely nest under the two-piece double-hinged doors. When doors are opened, the gates provide containment, but can also be opened from either side or removed as convenience dictates.

The gates can be snapped on at any location and additional gates can be added to the system.

The gates can be snapped on at any location and additional gates can be added to the system.

Fast and convenient access with dynamic cable containment.

The system used to mount plastic cable support fingers is common to all cable managers in every series. Any combination and arrangement of fingers can be installed on the mounting rails. The same universality is applied to the snap on hinges of all doors and gates. This interchangeability allows any RCM+ cable manager to be modified in the field to accommodate a broad range of applications. This also provides for adaptability to meet any future changes required.

Field modifiable features reduce future costs.

Call (866) 342-3721 Or Click On The Chat Button At The Top Of The Page To Talk To One Of Our Representatives

Side Mount

Side Mount

Data Cabinets- Racks

Data Cabinets- Racks

Snake

Tray

Snake

Tray  Snake

Tray

Snake

Tray